Syngas-to-olefins (STO) is an emerging international catalytic technology route in recent years. It aims to integrate functions such as syngas-to-methanol and methanol-to-olefins through multifunctional catalysts, thereby shortening the process, saving investment, and reducing material and energy consumption. This technology is of great significance for the high-quality development of modern coal chemical industry in China. Since 2022, it has been repeatedly advocated for vigorous development in documents issued by the National Development and Reform Commission and the Ministry of Industry and Information Technology. Usually, olefin synthesis requires a H2/CO (hydrogen-carbon ratio) > 2 in the feedstock, leading to substantial CO2 emissions from coal-based syngas in the water-gas shift (WGS) section. Additionally, most of the hydrogen and oxygen in the feedstock form water, essentially converting the most expensive component (hydrogen) into wastewater.

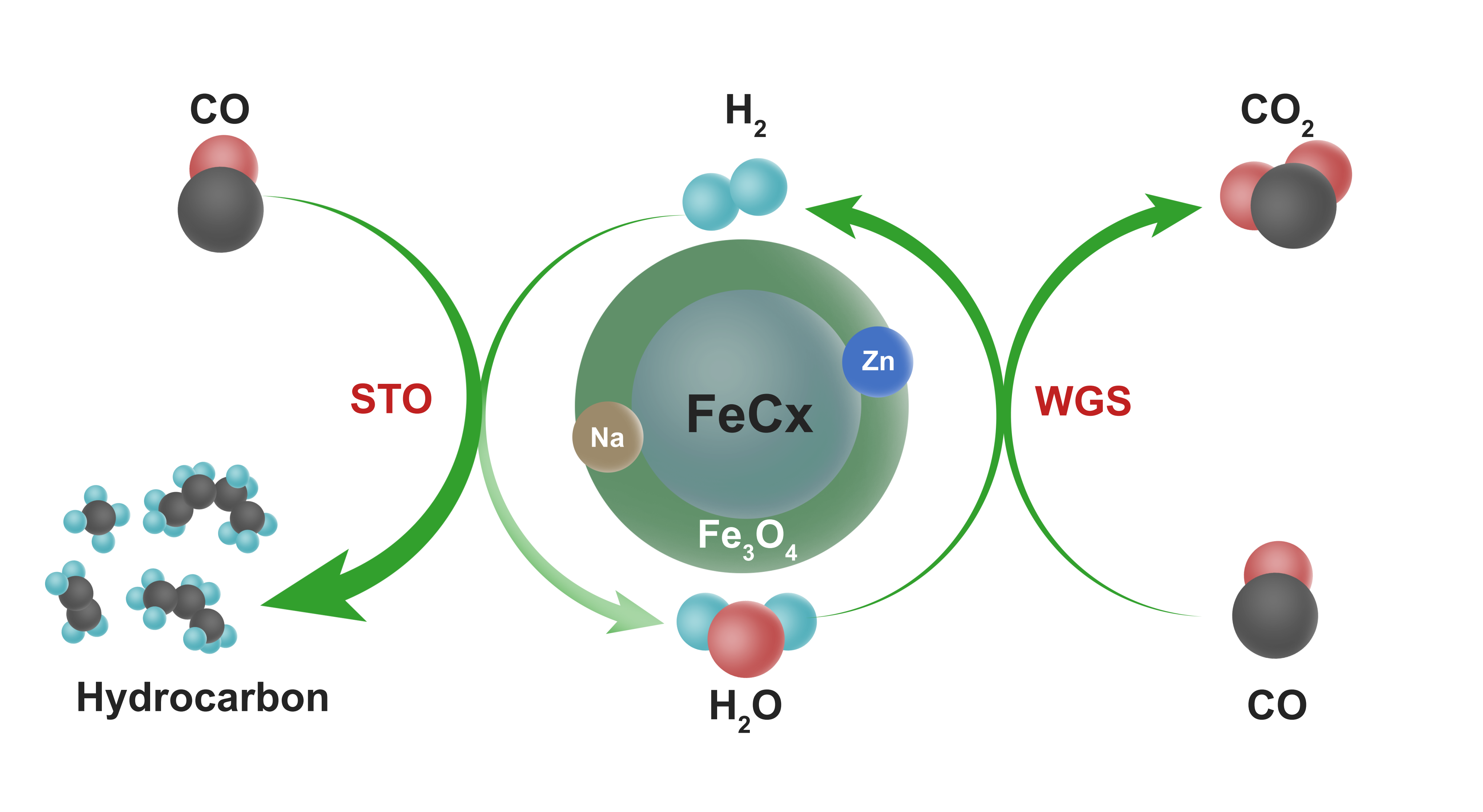

To meet the coordinated demands of high process conversion, high product yield, and low emissions, and addressing the drawback that traditional catalysts are prone to deactivation by water oxidation, the team reported a sodium-modified FeCx@Fe3O4 core-shell catalyst. This catalyst integrated WGS and STO functions at the micro-interface. The WGS reaction in-situ converted water generated during the process into hydrogen for olefin synthesis, increasing the hydrogen atom economy of the target products to 66%~86% while significantly suppressing the excessive oxidation of the catalyst by water. The process followed a rule: the lower the feedstock hydrogen-carbon ratio (between 1 and 3), the higher the hydrogen atom economy. These values far exceeded the theoretical (50%) and actual (43%~47%) hydrogen atom economy of the traditional WGS-methanol synthesis-methanol-to-olefins route. The team verified this coupling mechanism through isotope tracing and experiments blocking the WGS pathway, and quantitatively determined the contribution of the WGS reaction on the catalyst, laying a foundation for the rational design of such catalysts. Furthermore, experiments blocking the WGS pathway proved that the probability of CO2 generation through the STO route was very low.

The team demonstrated that high hydrogen atom economy was closely related to the activity matching of the catalyst's two functions. The WGS reaction could be initiated at low temperatures, while olefin synthesis activity relied on higher reaction temperatures. Under the reaction conditions of 350 °C and 2 MPa, using feedstock with a hydrogen-carbon ratio of 1.5, the single-pass CO conversion rate reached approximately 95%, olefin selectivity exceeded 75% (based on hydrocarbon products), and hydrocarbon yield reached 33 wt% (based on feedstock). The catalyst maintained stable performance after 500 hours of continuous reaction testing.

Figure: Under the coupling effect of water-gas shift (WGS) and syngas-to-olefins (STO), both hydrogen atom economy and olefin yield are improved.

Due to the breakthrough in improving the hydrogen atom economy of syngas conversion, the corresponding WGS-STO coupling route using this catalyst reduces total steam consumption, total wastewater generation, and total CO2 emissions compared with the traditional route. The overall environmental factor is reduced by 46%. The team is advancing the pilot-scale amplification of this technology to provide an alternative to existing coal-to-olefins production technologies. Meanwhile, its ability to efficiently utilize hydrogen feedstock may promote research on new STO routes using syngas derived from green hydrogen (expensive, driven by renewable electricity) and CO produced by CO2 electrolysis in the carbon neutrality era.

Chang Gao (Ph.D. student, Class of 2022), Wenlong Song (Ph.D. student, Class of 2018), and Huiqiu Wang (Ph.D. student, Class of 2019) from the Department of Chemical Engineering, Tsinghua University, are the co-first authors of this study. Professor Weizhong Qian and Research Assistant Chaojie Cui from the same department are the co-corresponding authors. This research was supported by the National Key R&D Program of China.

Paper link: https://doi.org/10.1126/science.aea0774